Making a difference for our customers

368

Model: WTK-KC1625 Category: Oscillating Knife Cutting

USD

5000$-21000$ FOB Qingdao

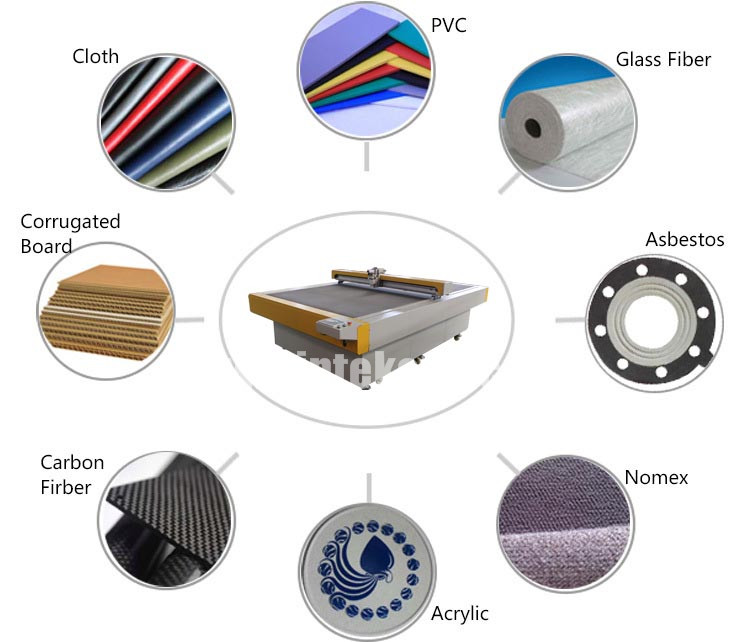

Oscillating knife cutting machine is a good choice for cutting rubber,leather,fabric,cardboard,plastic,paper,rubber,cloth,foam,ect.Oscillating knife cutting machine with good choice.

Functions of Oscillating knife cutting machine:

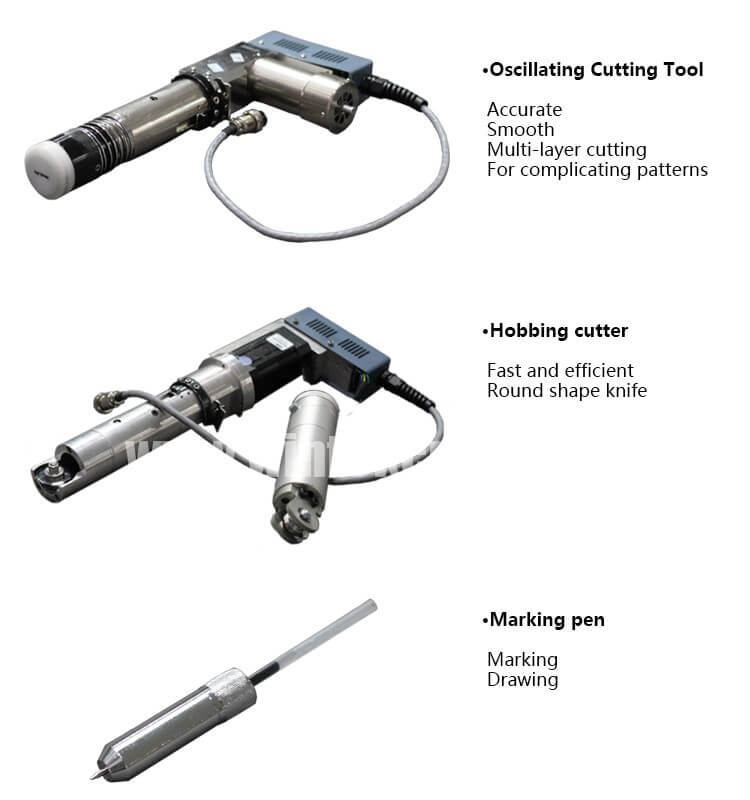

(1)Cutting function of oscillation tool

It can cut many different materials (such as corrugated paper, cardboard, offset paper, grey board, rubber,honeycomb board, PP,PE,PVC, gasket, leather ,carpet and mat )

(2)Folding function: It can fold corrugated paper, card paper and offset board into perfect folding line.

(3)Function of dotted line: It is used to fold them after half cutting corrugated paper and grey card paper, and to cut dotted line.

(4)Location: Location with laser.

(5)Drawing function : It can draw various high precision drawing cutting materials: corrugated board, foam, PVC, styrene, Coroplast, Celtec, magnetic film, adhesive vinyl, leather, rubber, fabrics, high intensity reflective films, paper, cardboard, polystyrene, magnetic films, vinyl etc.

(6)Punching function: It can punch hole on the material, such as leather,carton, pvc, carpet and mat ,etc.

Videos of oscillating knife cutting machine :

Samples by Oscillating knife cutting machine :

Details show of Oscillating knife cutting machine :

Technical Parameter of Oscillating knife cutting machine :

|

Model

|

WTK-KC1511

|

WTK-KC1526

|

WTK-KC2030

|

|

Max. Cutting size

|

1500*1100mm

|

2500*1600mm

|

3050*2050

|

|

Power

|

11KW

|

12KW

|

14KW

|

|

Multi-functional Tool Head

|

Thorough cutting/Kiss cutting/Creasing/Plotting/

Lasor Locating/Automatic Table-level measuring |

||

|

Security configuration

|

High sensitive infrared induction (optional)

|

||

|

Travelling speed

|

Max. 1200mm/s

|

||

|

Cutting speed

|

Max. 800mm/s (Depending on different material type)

|

||

|

Movement speed

|

1200mm/s Maximum 1200mm/s

|

||

|

Cutting speed

|

Maximum 800mm/s (set according to different cutting materials)

|

||

|

Cutting material

|

Corrugated paper, PVC expansion sheet, kt sheet, thick foam, grey board,

paperboard, car sticker, adhesive Sticker, etc. |

||

|

Cutting thickness

|

Maximum 5-mm (set according to different materials)

|

||

|

Material fixing method

|

High power vacuum absorption and intellectual partition

|

||

|

Repeated positioning accuracy

|

Maximum 0.01mm

|

||

|

Mechanical Precision

|

Maximum 0.02mm

|

||

|

Drive system

|

Steel wire synchronous belt , AC servo motor, linear guideway

|

||

|

Control system

|

digit RISC core cpu + large scale programmable logic array

|

||

|

Operating mode

|

operation platform + data output control software

(operation platform can be divided into connected and separated parts) |

||

|

Display mode

|

Chinese and English liquid crystal touch screen

|

||

|

Data transmission method

|

Ethernet

|

||

|

Instruction system

|

HPGL compatible format

|

||

|

Buffer capacity

|

Standard 4GB

|

||

Advantages of Wintek oscillating knife cutting machine :

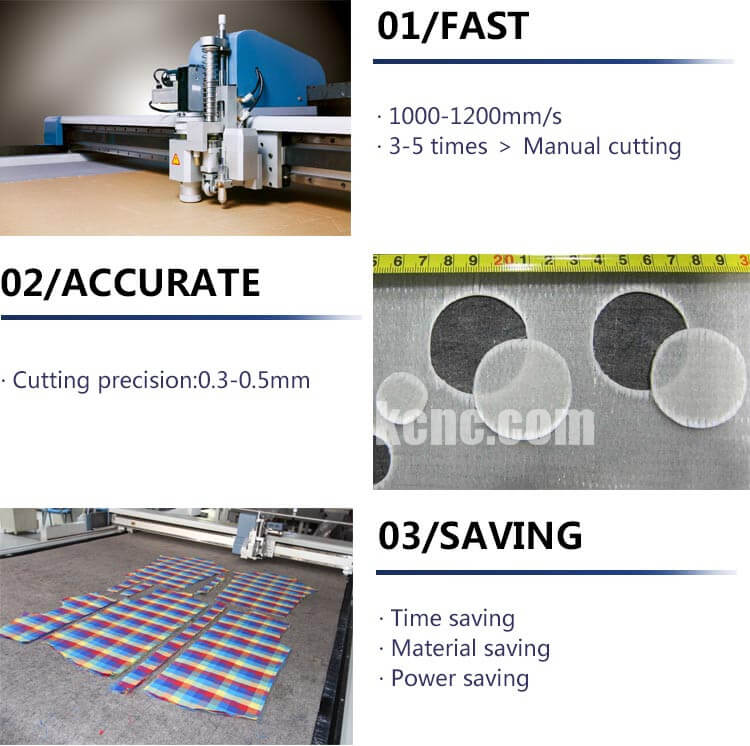

1.Fast

Max. cutting speed: 1200mm/s

Wintek cutting machine is 3 to 5 times faster than traditional manual cutting.

2. Material Saving

Wintek cutting machines are computerized

Accurate and material saving.

3. Compatible

Our cutting machines support any design software which can output files in DXF or PLT format.

Eg: AutoCad, Coreldraw, AI, etc.

4.User friendly

All the sharp turnings can be controlled on the machine.

A free training is supported at our company or on your site. We assure you can operate the machine.

Here have more models for choice :

Oscillating knife cutting machines