Making a difference for our customers

568

Model: WTJ1610-CCD Category: Co2 Laser Cutting Machine

USD

6500$-$9500 FOB Qingdao

Automatic ccd camera laser cutting machine with auto feeding device is a good choice for cutting leather shoes,clothing,wool felt,home fabric.

Working video of Automatic CCD Camera laser cutting machine,auto feeding laser cutting machine :

Parameter of Automatic CCD Camera laser cutting machine,auto feeding laser cutting machine :

|

Parameter |

|

|

Name |

Automatic CCD Camera laser cutting machine, |

|

Model |

WTJ1612-CCD |

|

Working area |

1600*1200mm |

|

Cooling ways |

Water cooling |

|

Engraving speed |

0-40000mm/min |

|

Cutting speed |

0-40000mm/min |

|

Laser power |

150w (80w,100w,130w optional) |

|

Laser type |

CO2 laser,RECI brand,service life >10000hrs |

|

Laser output control |

0-100% controlled by software |

|

Min engraving size |

English letters,1*1mm |

|

Scanning resolution |

4000DPI |

|

Locating accuracy |

≤0.01mm |

|

Controlling software |

DSP controlling system,RDWORKS V8 |

|

Format supported |

DST,PLT,DXF,AI,LAS,BMP,JPG,PNG,etc |

|

Software environment |

Windows xp/7/8/10 |

|

Compatible software |

Coreldraw,Autocad |

|

Color separation output |

Yes |

|

Slope engraving |

Yes |

|

Driving system |

Stepper motor |

|

Auxiliary accessories |

Exhaust fan,fume tubes,air pump |

|

Working table |

Stainless steel net +Auto-feeding working table |

|

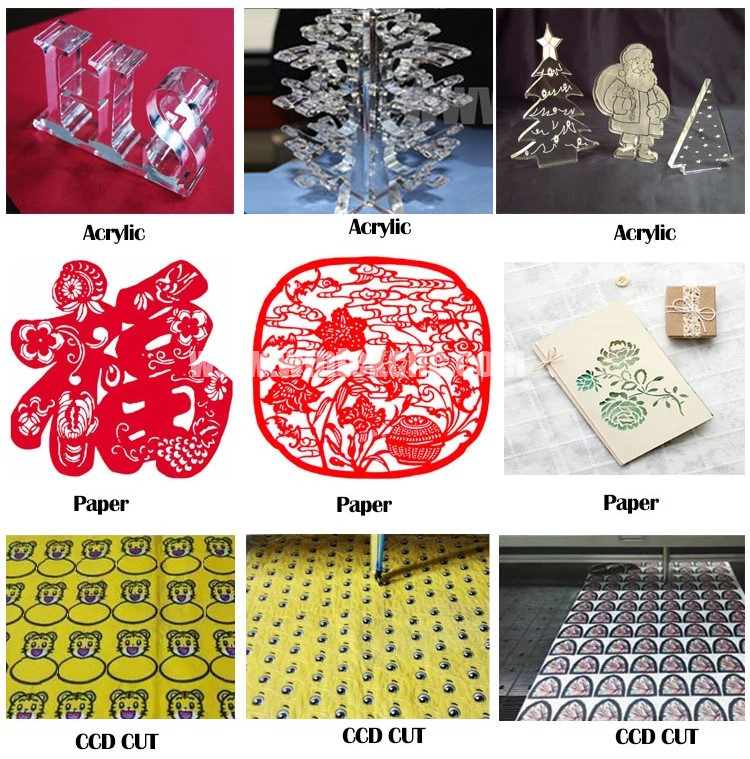

Applicable materials |

Fabric,leather,wood,MDF,glass,stone,plastic,rubber , etc |

|

Working environment Temperature |

0-45℃,Humidity5-95%(no condensate water.) |

|

Power supply |

110v/220v,50hz/60hz |

|

Weight |

550kg |

|

Dimension |

2100*1400*1800mm |

Applicable Industry of Automatic CCD Camera laser cutting machine,auto feeding laser cutting machine

Optional : Aufo feeding device with autocorrection

Features

1. 1 machine =10 manual work, traditional cutting, complex process, save labor costs.

2. Optional double beam asynchronous cutting, single beam cutting.

3. HD SLR camera automatic edge tracking, automatic feeding.

4. Automatic edge tracking, No drawing, Automatic contour generation.

5. Precise cutting, the cutting accuracy of 1mm or less.

6. Automatic feeding, can save feeding time and labor costs.

7. The feature points are positioned and cut according to the model.

8. Minithoracotomy and no deformation, no burr on the whole, more natural, greatly enhance the brand image

9. High speed, high precision cutting, and high cutting efficiency

10. Precision cutting without hair brim, the cutting brim strength could increase 40 times.